The Waterbury Co USA

Pocket Watch - Part 3

Full project photo

album Click here - opens new window

The first item of the day was to remove the two stuck hour

& minute wheels from the overnight soaking in WD40 and with extreme care

using a staking block and small tap from a watchmaker’s hammer, hay presto the

wheels free themselves.

|

| The hour and Minute wheels separated. |

Next to remove the case from rust remover and it has freed

up the completely stuck stem. Removed the Crown, spring and Stem, another

broken part is the "Winding and Setting wheel" attached to the stem

as a lot of teeth are missing. This could be the part that makes this restoration

impossible as I do not have any gear cutting equipment, so fingers crossed that

a replacement part or a "parts movement" comes up for sale!

|

| Removed the Crown, spring and Stem |

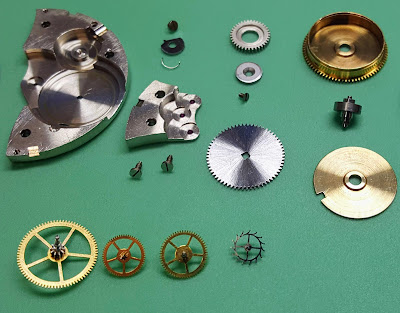

Next, all parts given a clean and then check out what else is

needed to get the movement up and running.

|

| All the parts are given a clean |

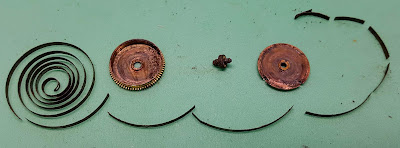

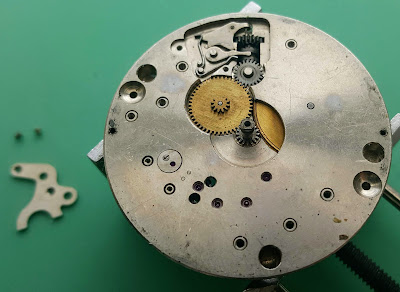

Refitted the crystal, New Mainspring and after a bit reaming

with my small broaching set a set of replacement hands fitted.

|

| New Mainspring fitted. |

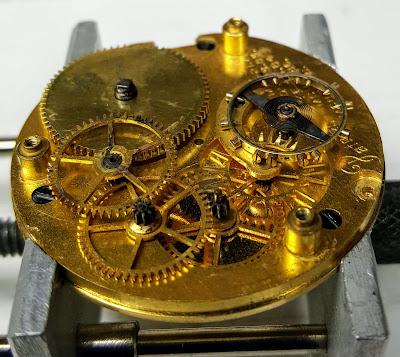

The following items needed:

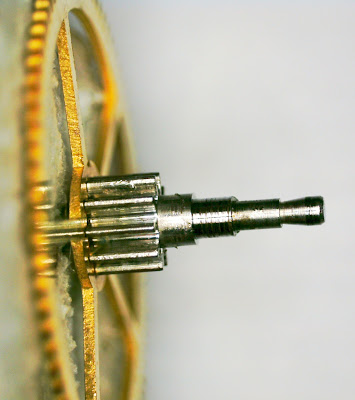

Setting and Winding Gear (teeth broke) will have to try and

source one as it needs replacing, second and third wheels top pinions are

broken (Will do them the next time I have my watchmakers lathe set up),

replacement Hairspring (Will have to look in the spares box and time

hairspring). Replacement regulator arm, click spring and a case bow also

needed!

|

| second and third wheels top pinions are broken |

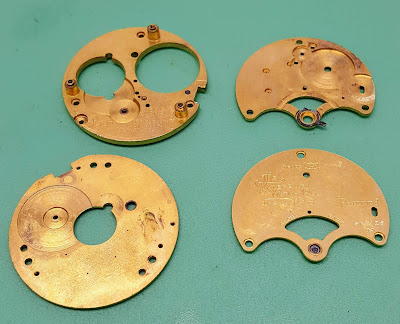

Reassembled the movement and placed back in case just to

learn how this unusual movement with four “main plates” and the duplex

escapement goes together!

|

| Reassembled the movement. |

So now watch is back in its box until I find the parts,

which could take some time!