TIM Lever 7 Jewels Shock Protected Stopwatch. Part 6

Two Lathe Sunday as I manufacture a new Fly-Back Pusher.

Full photo album Click Here - opens new window

|

| Two Lathe Sunday |

Stage 1: Start off by bringing

out my Unimat SL 1000 Lathe to first turn down the 4mm stainless steel rod to

2.5mm at length of 11.5mm.

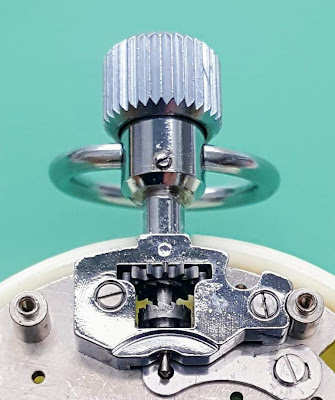

Stage 2: Turn down to 2.mm for a

length of 10.5mm, check that the pusher fits into the fly-back pendant tube,

which it does snugly.

Stage 3: 3mm of the end of work

turn down to 1.7mm for the tapping the thread for the crown.

Stage 4: Tap the (No17) thread

with threading plate and check the crown fits correctly.

Stage 5: Turn the workaround in

the chuck and part off.

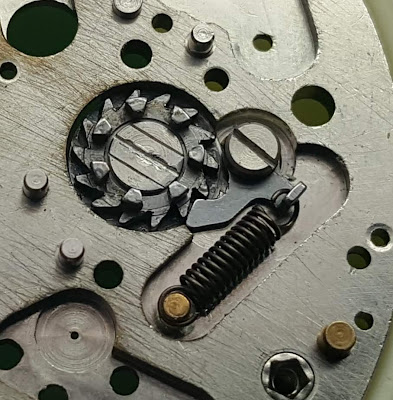

Time to get out of its box is my

vintage G. Boley "Bevelled-bed" Branded "Telco", T.C. &

M. Ltd

6.5mm watchmakers lathe.

I needed this lathe so I could

use the file rest and also set spring-loaded indent arm to lock the spindle.

Filed a Screw slot using a number 6 cut

slotting file, now time to see if my manufactured pusher works,

Time to clear up the workshop and

put the lathes away and set the bench for completing the stopwatch tomorrow!