Smiths Braille pocket

watch A1866 movement. Reassembly

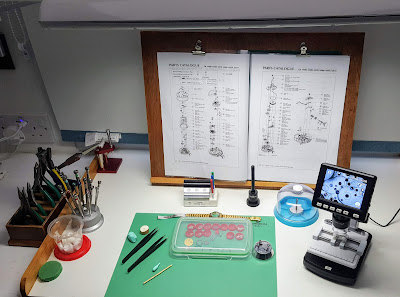

Time spent in the workshop yesterday was all about reassembling the

“Peaky Blinders” Smiths A1866 movement.

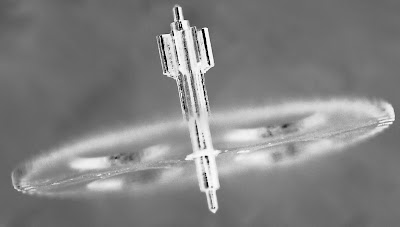

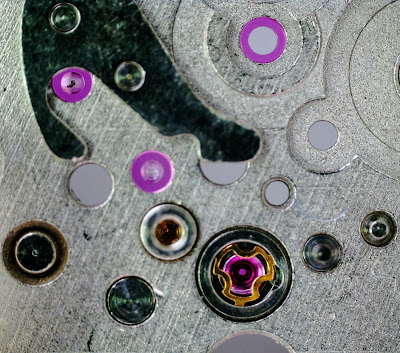

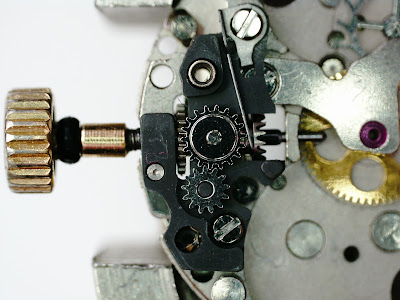

I am well happy, I removed the jammed Train, Escape wheels without damaging any pivots, and the completely jammed train wheels are now running smoothly before replacing Pallet Fork.

And as you can see from the video all went well, it’s up and

running.

.

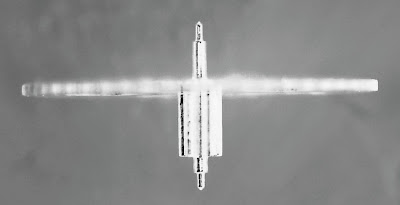

Now have to decide what to do with the hands, as there is a lot of chrome missing on them.

I now have to thank Watch Repair Lessons Facebook group

member Roger for all the information on the SMITHS Braille Pocket Watch he has

put in a comment on my last post.

I was thinking that I may paint the hands black, and Roger

informs me that “The hands are much thicker and shorter than a standard watch

when you got a replacement watch from Smiths the hands where mat Black”. So

Black, they will be.

Plus do a bit of research on how to make the Dial presentable!