I had an interesting job in the workshop today, which was to

replace the movement on a Vostok Europe - Expedition North Pole -1 watch

Full Photograph album of the replacement movement

Full Photograph album of the replacement movement

The Expedition North Pole watch was named after the first

Soviet, manned, drifting polar station. The North Pole-1 polar station was

opened on June 6, 1937, some 20 km from the North Pole and operated for 9 months

during which the ice floe travelled 2,850km.

The expedition ended 75 years ago.

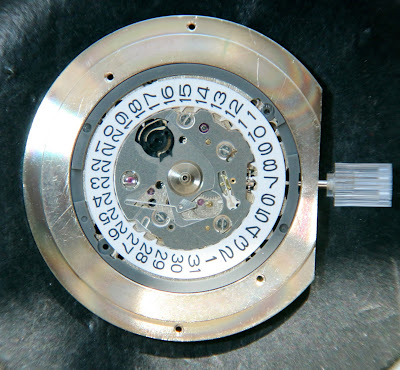

The movement is a Japanese-automatic Movement NH35A –

5955195 Made by SII (Seiko)

When replacing the dial, I could not line up

the date numbers thought the dial window!

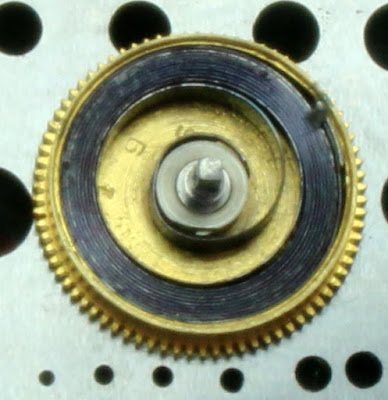

Can you spot the difference in the old movement

and the new replacement movement?

The numbers on the date rings are printed 90% to each other. So I had to exchange the date rings.

|

| Job Done |