TIM Lever 7 Jewels Shock Protected Stopwatch. Part 3

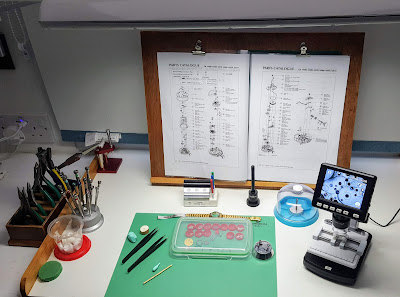

Only a short time in the workshop today working on the TIM Lever 7 Jewels Shock

Protected Stopwatch.

All parts cleaned,

ready to assemble.

|

| All parts cleaned, ready to assemble. |

First I refitted and then polished the

crystal with the bezel.

|

| Polished the crystal |

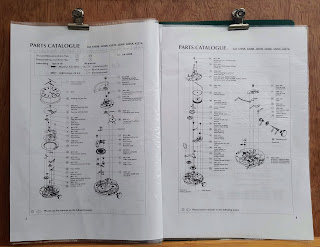

Started the assembly of the BFG

Calibre 410 movement.

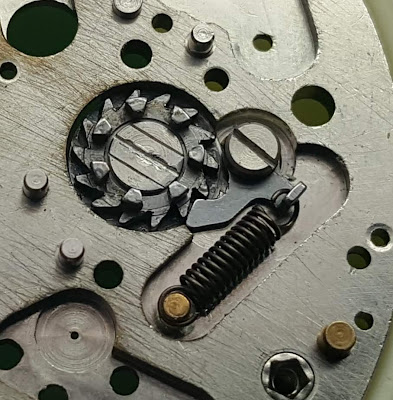

Grease and fit the Pillar Wheel

with the Left-Handed thread screw, then replace the Pillar Wheel jumper and

spring.

|

| Pillar Wheel jumper and spring. |

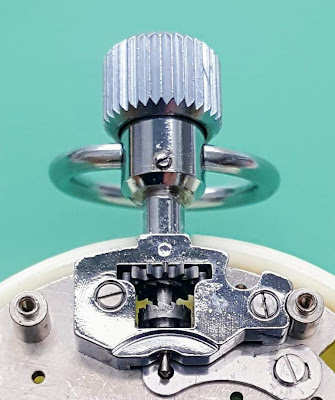

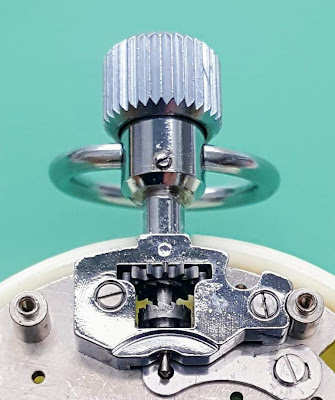

Turn the movement mainplate and

refit the Yoke. Then refit the Stem Cock, then I have to file a cut out in one

of my plastic movement holders so movement lies flat in the holder.

|

| Refit the Yoke. Then refit the Stem Cock |

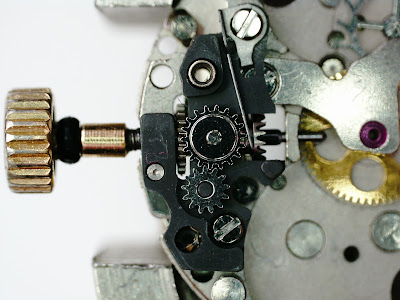

Grease and refit the Stem,

Winding Pinion and Clutch wheel.

|

| Refit the Stem, Winding Pinion and Clutch wheel. |

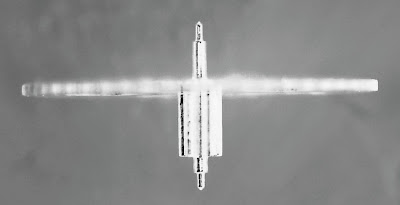

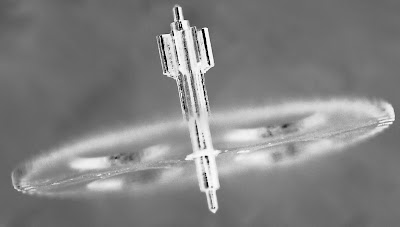

Grease and refit the operating

lever and the fly-back lever.

|

| Refit the operating lever and the fly-back lever. |

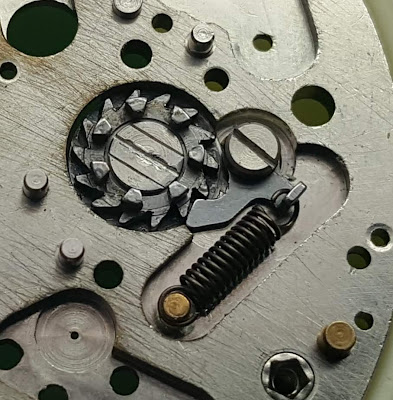

Grease and refit the blocking lever

for the second's wheel.

|

| Refit the blocking lever for the second's wheel. |

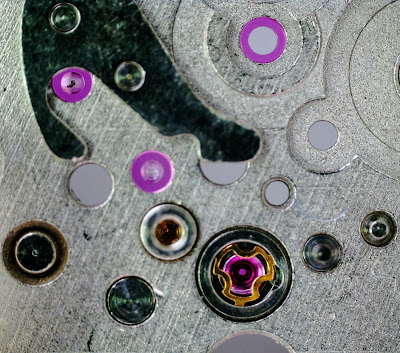

Remove and clean the lower

Antishock jewel, then replaced the cleaned lower Antichoc jewel.

|

| Removed, cleaned and replaced the lower Antishock jewel |